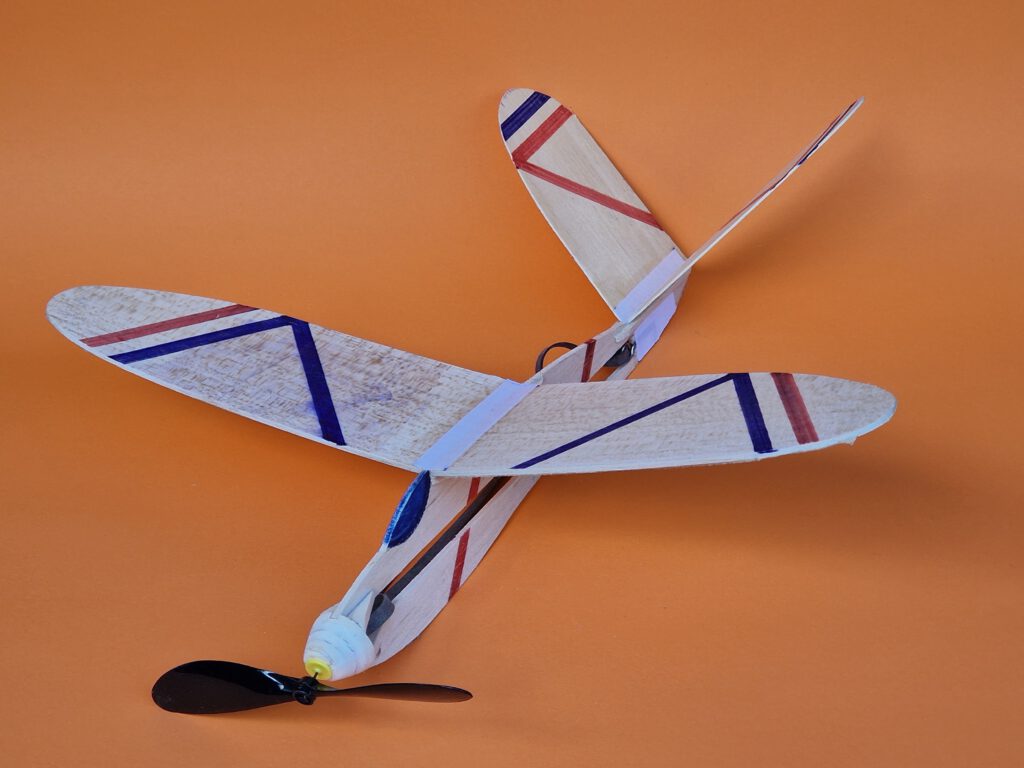

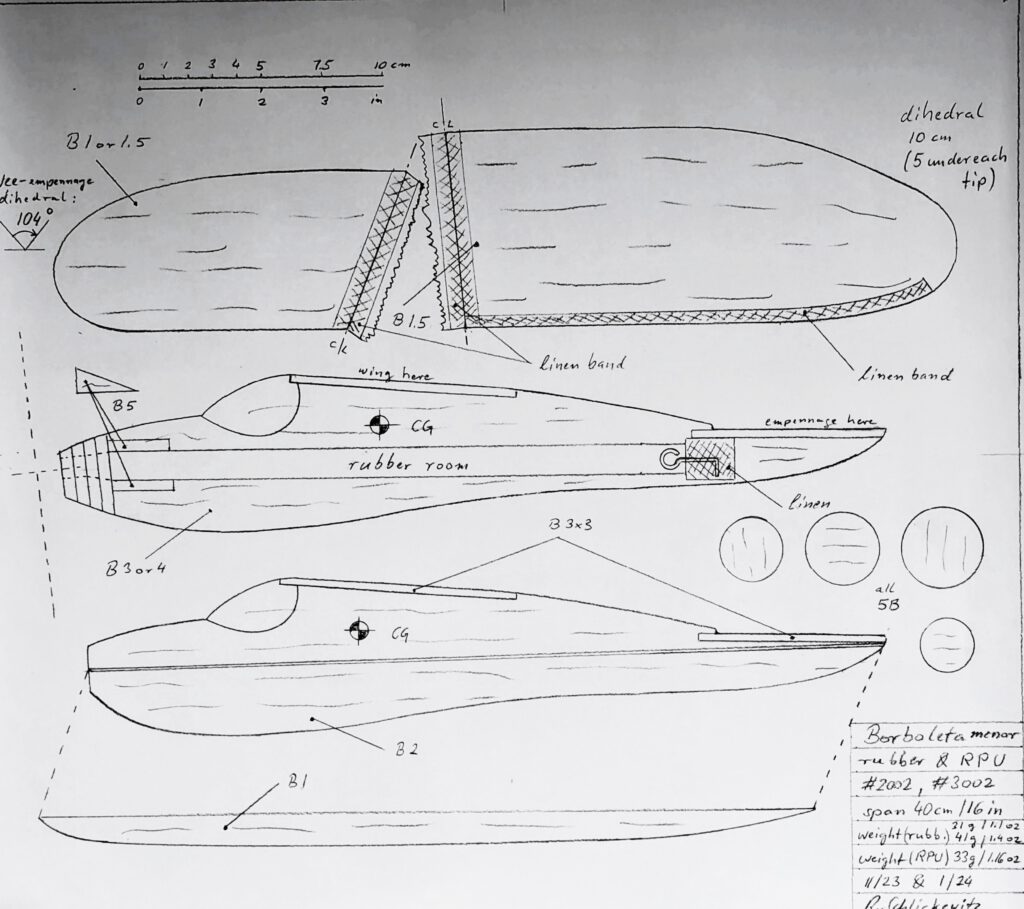

Span 40 cm / 16 in

Weight 31/41 g / 1.1/1.4 oz

The concept:

- few parts

- easy to build

- high-wing monoplane

- V-tail

- good flight characteristics

- two versions, one for built-in rubber motor (here) and the other for RPU 20

Name: As the combination of wing and empennage somehow looks like a butterfly seen from above or below I thought Borboleta, the Brazilian-Portuguese equivalent to butterfly, could be an appropriate name. Menor means smaller.

Building the rubber powered balsa profile-fuselage model Borboleta menor.

Materials:

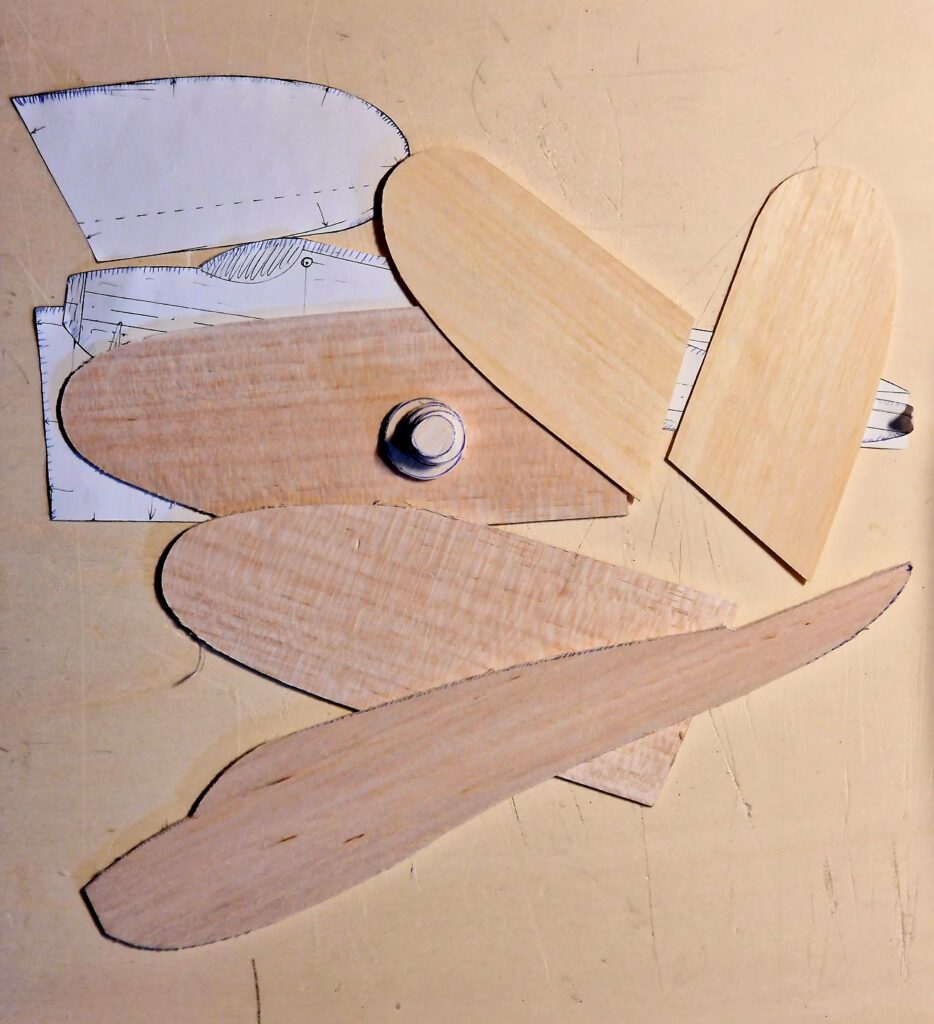

Fuselage: B 3 or 4; fuselage nose parts: B 5; nose supports (triangles): B 5; rubber hook: piano wire 1.2 or 1.5 mm diameter; wings: B 1.5 or 2; wing supports: B strips 3 x 3 or 5 x 5; V-tail: B 1; V-tail supports: B 3 x 3; linen band width 10 mm / ½ in; ballast: 3 g / 0.1 oz scrap metal or lead; one commercial airscrew 6 in diameter or more; greyish-black rubber.

Assembly:

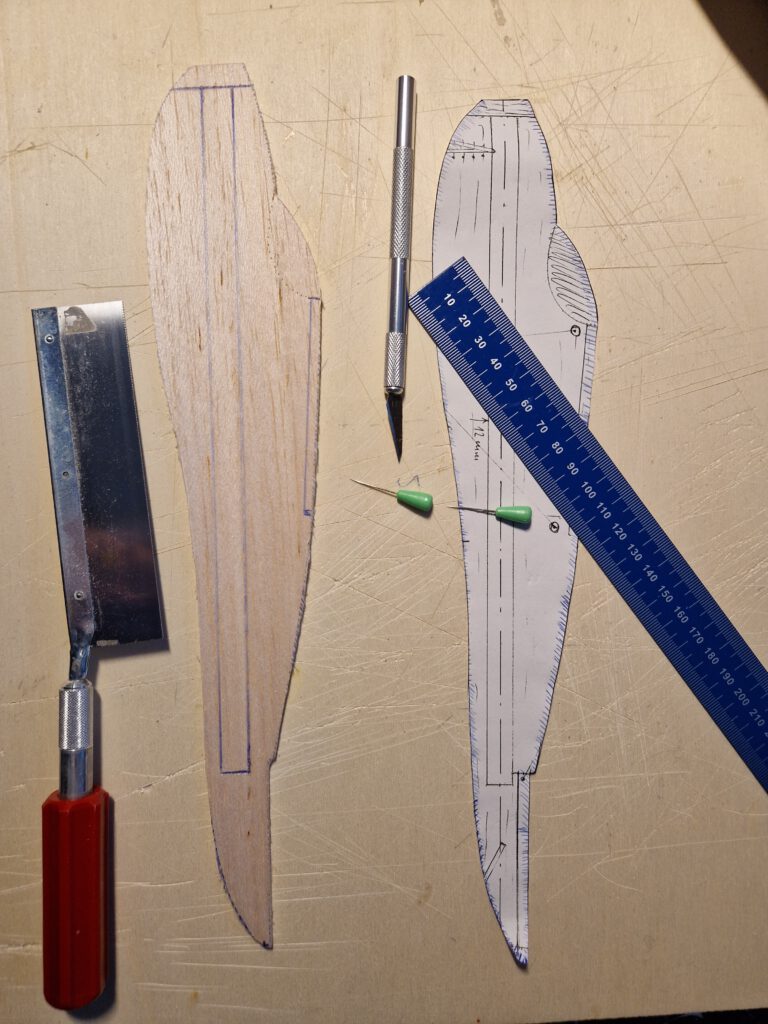

Cut out balsa parts in accordance to plan (photo). Sand well. Transfer outlines of cabin etc. from paper to wood with pen.

Wing:

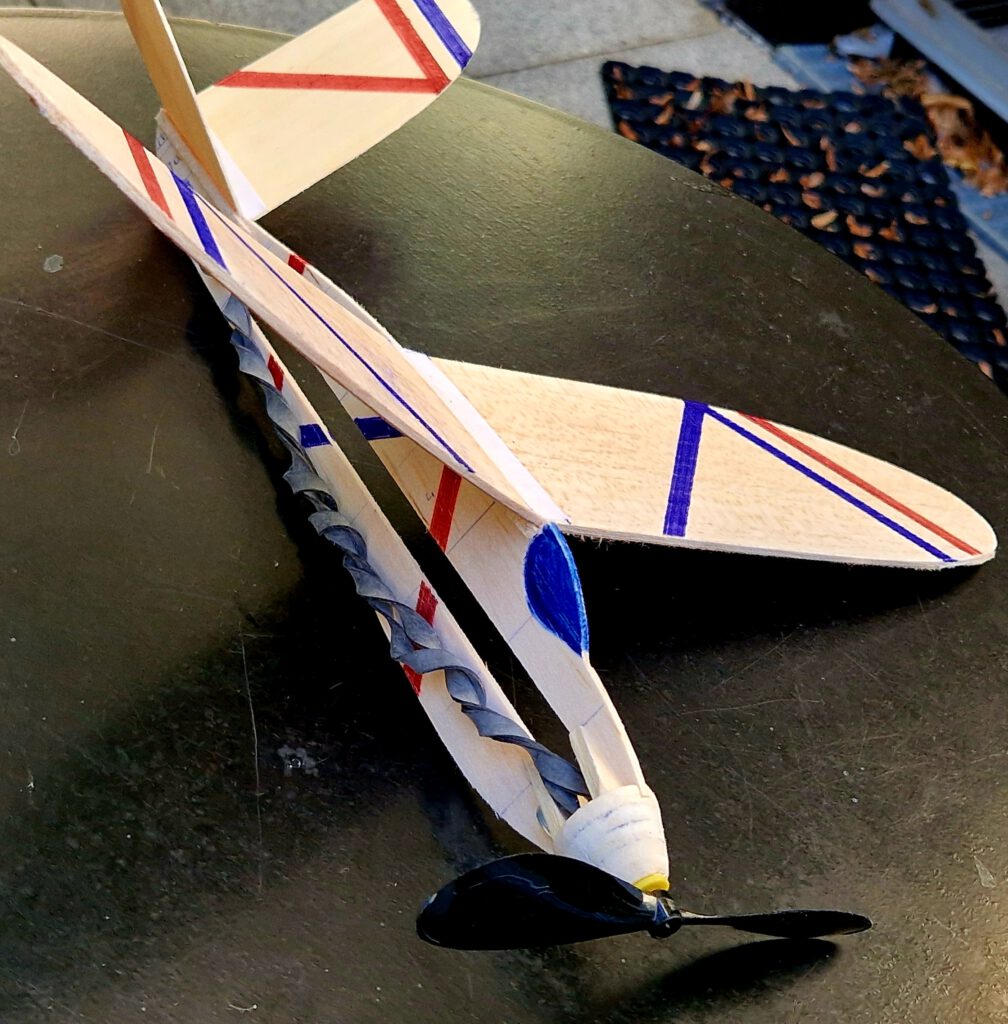

Wing consists of a right and a left wing half. Reinforce both wing half leading edges with linen band or with a B 1 strip on its underside. Let dry. Fix one wing half on building board with needles. Underlay the other wing half’s tip in accordance to required dihedral. Join both halves and cover wing center area with linen band (photo). Let dry. If wing has the tendency to rest only on one side then it is too heavy on this side. To compensate imbalance disperse an amount of white wood glue on the opposite wing tip area. Do it if necessary twice until balance is obtained.

Fuselage:

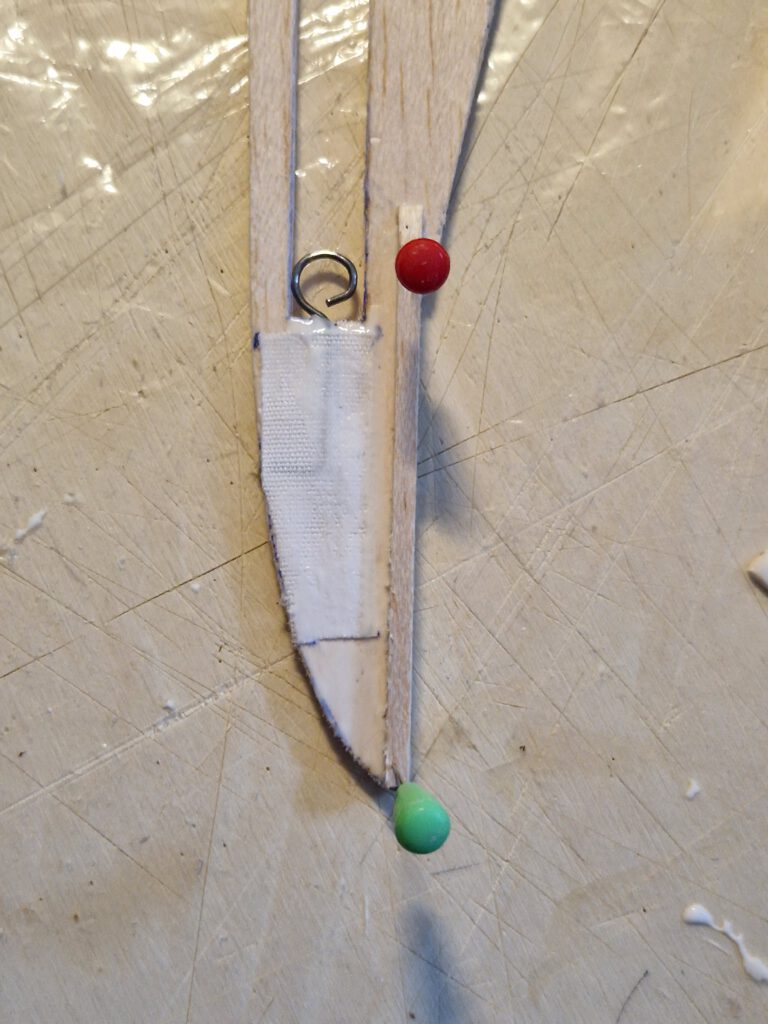

Bend as shown on plan piano wire into given hook shape. Carve out with knife and round file seat for rubber hook on left or right side of fuselage. Cement hook in place and cover hook area generously with glue and linen band. Let dry.

Cement B 5 nose parts one on the other as shown on plan and let dry. Sand well than treat this part with balsa putty. When dry sand again. May be this procedure has to be repeated. When the nose part is smooth you can start to carve out opening which holds prop-bearing. Start from behind and do it not in a hurry. A little electric drill machine can be useful.

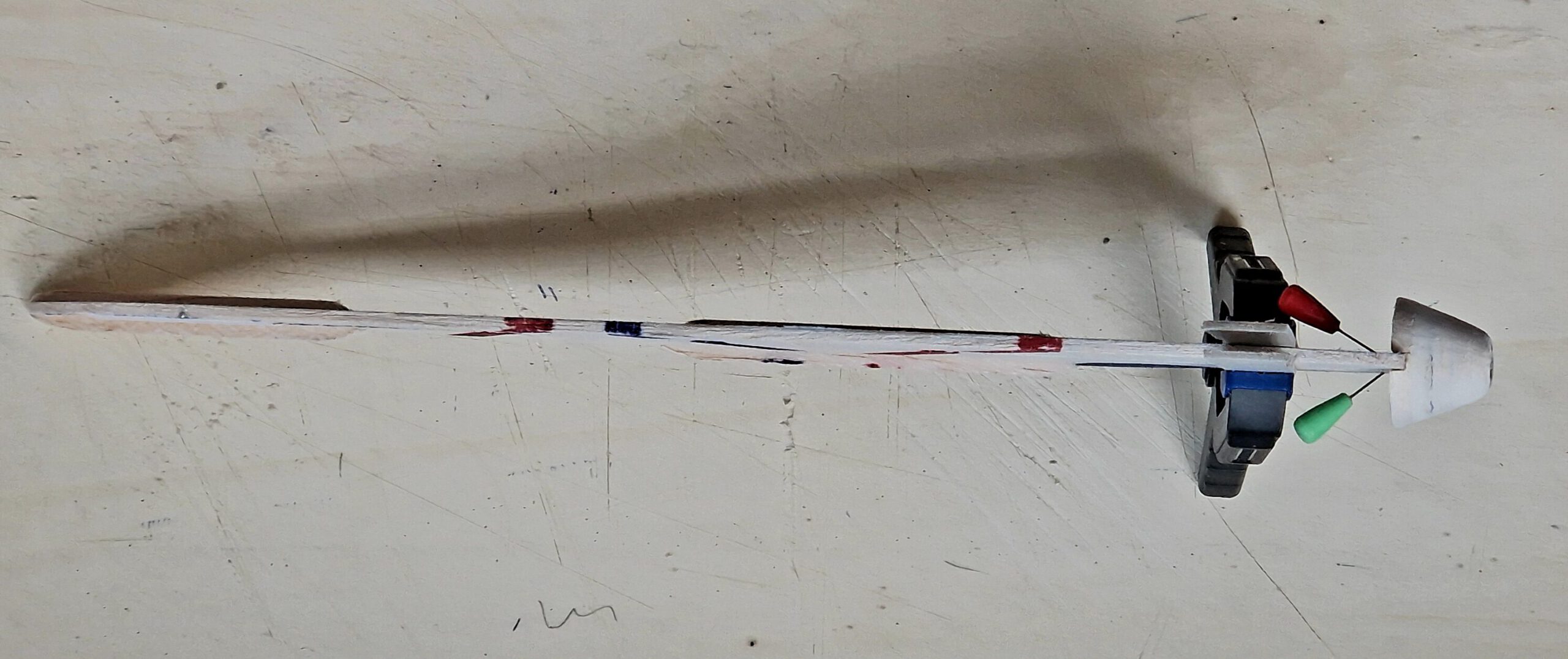

Cement nose on fuselage referring to photos. When dry add nose support triangles.

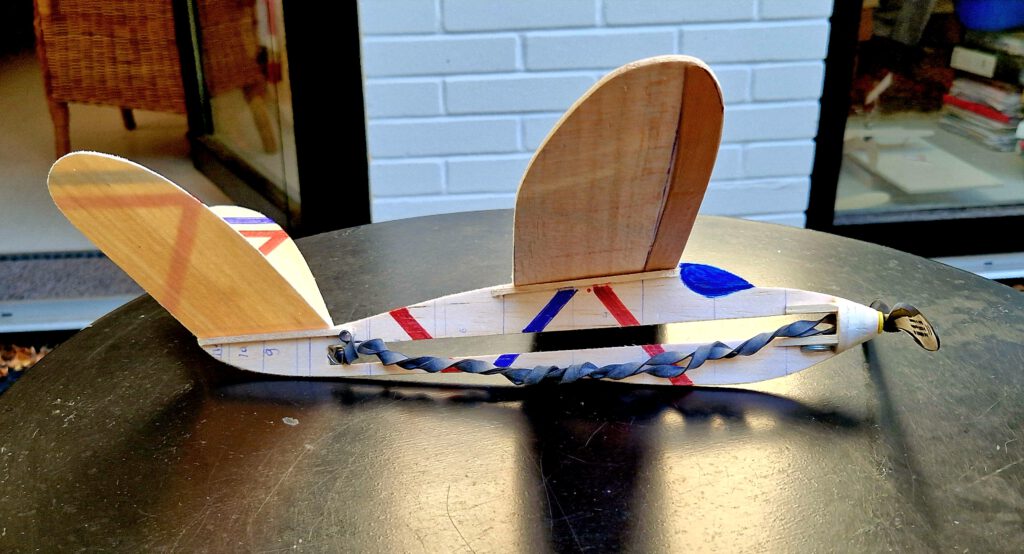

V-tail:

Reinforce both stabilizer leading edges with linen band on their underside. Let dry. Fix one V-tail component on building board with needles. Use selfmade template to get the other component into given angle and cement (photo). Visual check symmetry from all sides. Let dry.

Final Assembly:

Put fuselage on a so called “third hand”. Cement wing on fuselage supports using needles to hold in place. Doublecheck visually symmetry. Let dry. This procedure is to be followed by attaching the V-tail onto the fuselage end in the same manner.

Use a piece of lead or scrap metal to balance model at given position.

Remember correct center of gravity (CG) is essential for successful flights.

Size bol başarılı uçuşlar diliyorum! (Prajem vel’a príjemných letov!)

Leave a Reply