Span 52 cm / 21 in

Weight 45 g / 1.6 oz

The concept:

• Triple tail as known from the Lockheed Constellation

• Shoulder-wing monoplane

• Easy to build

• Good flight performance

• detachable landing gear

• 6 in. Airscrew

Eire is the Irish Gaelic name for Ireland. Belle is French and means beauty.

The Irish carrier Aer Lingus introduced Lockheed Constellations in green livery in 1948.

Building note:

Some of the photos show first test model with profiled wing. The final product instead has an unprofiled sheet wing for ease of construction. Performance of both models turned out to be nearly equivalent.

Building the rubber powered balsa profile-fuselage model Farmington Fairytale.

Materials

Fuselage: B 3 or 4; fuselage nose parts (rounded): B 3; fuselage nose parts (strips): B 3; rubber hook: piano wire 1.2 mm diameter; wings: soft B 2; wing supports: B 3 x 3 strips; horizontal stabilizer: stiff B 1 or 1.5; horizontal stab supports: B 3 x 3 strips; fins: B 1; fin support strips: B 3 x 3; linen band width 12 mm / ½ in; ballast: small piece of scrap metal or lead; one commercial airscrew 6 in diameter; black rubber.

Assembly

Cut out balsa parts in accordance to plan. Sand well (photo). Mark outlines before coloringfor professional results.

Wing:

Cement linen band around leading edges of both wing halves so that band forms a U around the leading edge. Let dry.

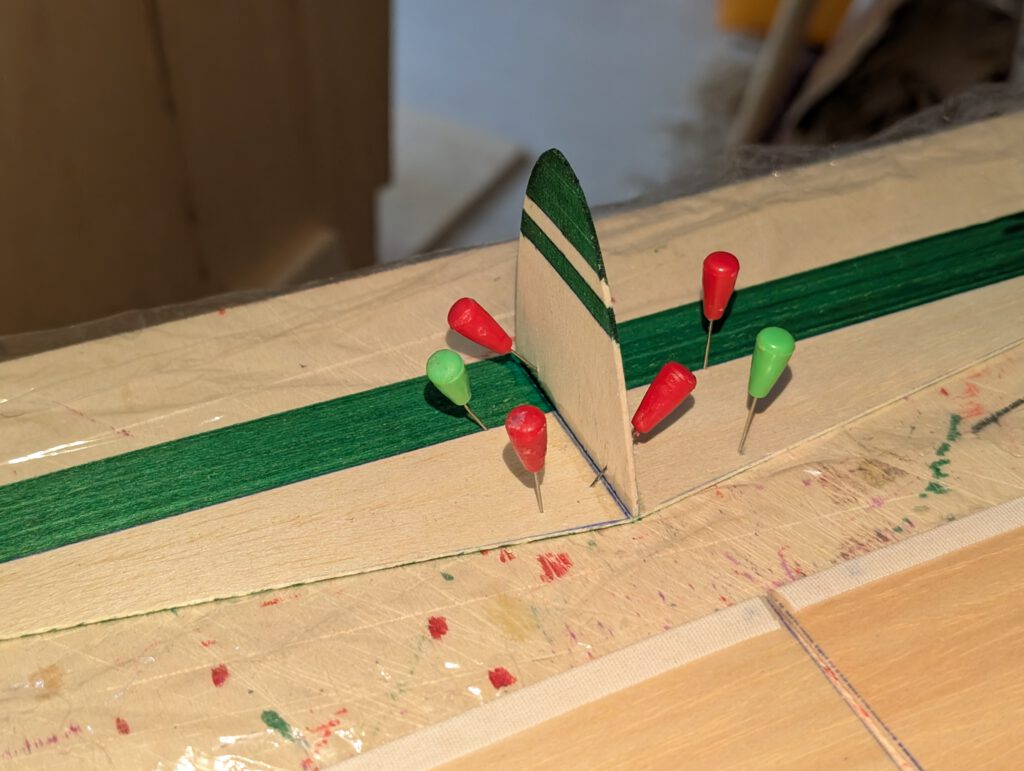

Pin one wing half on building board (photo). Underlay the other wing half’s tip at the indicated spot and at given dihedral. Cement both halves using linen to cover joining area

When dry check equilibrium. If there is a weight difference on one wing half, disperse a small amount of white glue near the tip of the other wing half’s underside and disperse it well. Do this if necessary twice until equilibrium is reached. Put aside and let dry.

Fuselage:

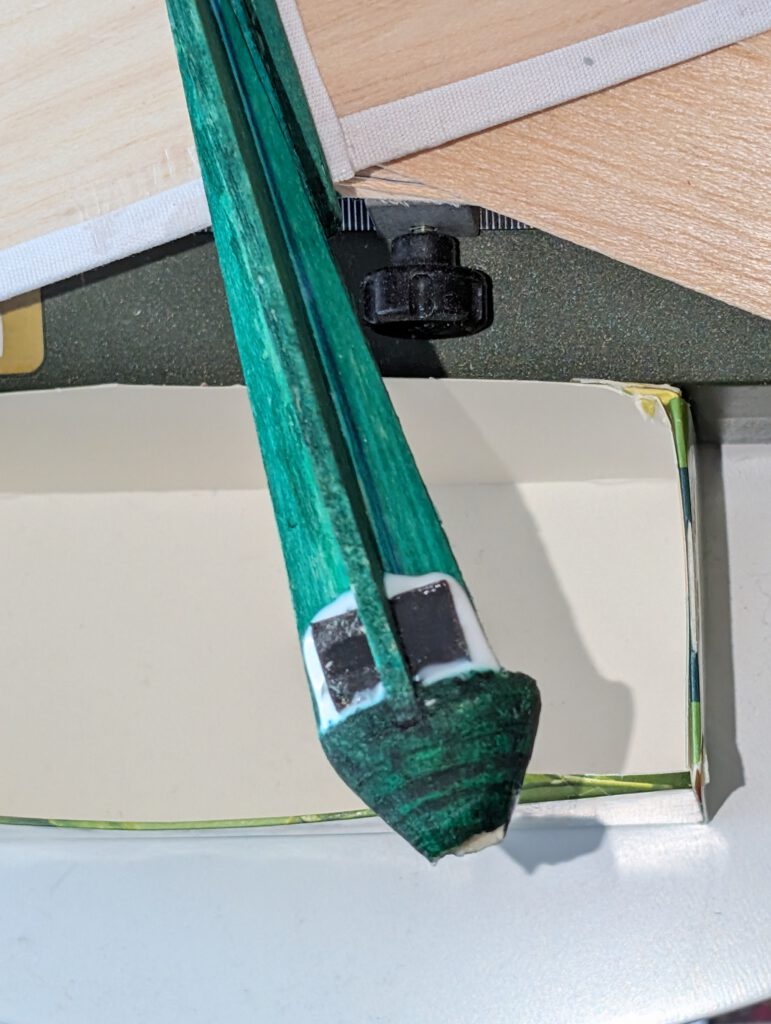

Bend as shown on plan piano wire into given hook shape. Carve out with knife and round file seat for rubber hook on left or right side of fuselage. Cement hook in place and cover hook area with linen band as seen on photos. Let dry.

Cement B 3 rounded nose parts one on the other as shown on plan and let dry. Sand well than treat this part with balsa putty. When dry sand again. May be this procedure has to be repeated. When the nose part is smooth you can start to carve out opening which will hold prop-bearing. Start from behind and don’t do it in a hurry. A little electric drill machine can beuseful.

Cement nose on fuselage according to plan and photos. When dry add elongated B 3additional fuselage side stiffeners, one on each side, as shown on plan.

Empennage:

Pin horizontal stabilizer on building board. Cement central fin on horizontal stab. Check symmetry and let dry. Cement balsa strips to both outer fin insides. Fix horizontal stab with central fin on “third hand”. Cement outer fins on horizontal stab. Hold with pins and check symmetry from all sides (photo). Let dry.

Final Assembly:

Fix fuselage on “third hand”. Cement empennage in its place on fuselage. Use pins. Check symmetry from all sides and let dry.

Cement wing on to its mount on top of both wing supports. Hold with pins and let dry. Watch symmetry!

A piece of lead or scrap metal may be used to balance model properly.

Remember correct center of gravity (CG) is essential for successful flights.

Palju edukaid lende! (सुखद उड़ानें हों!)

Leave a Reply