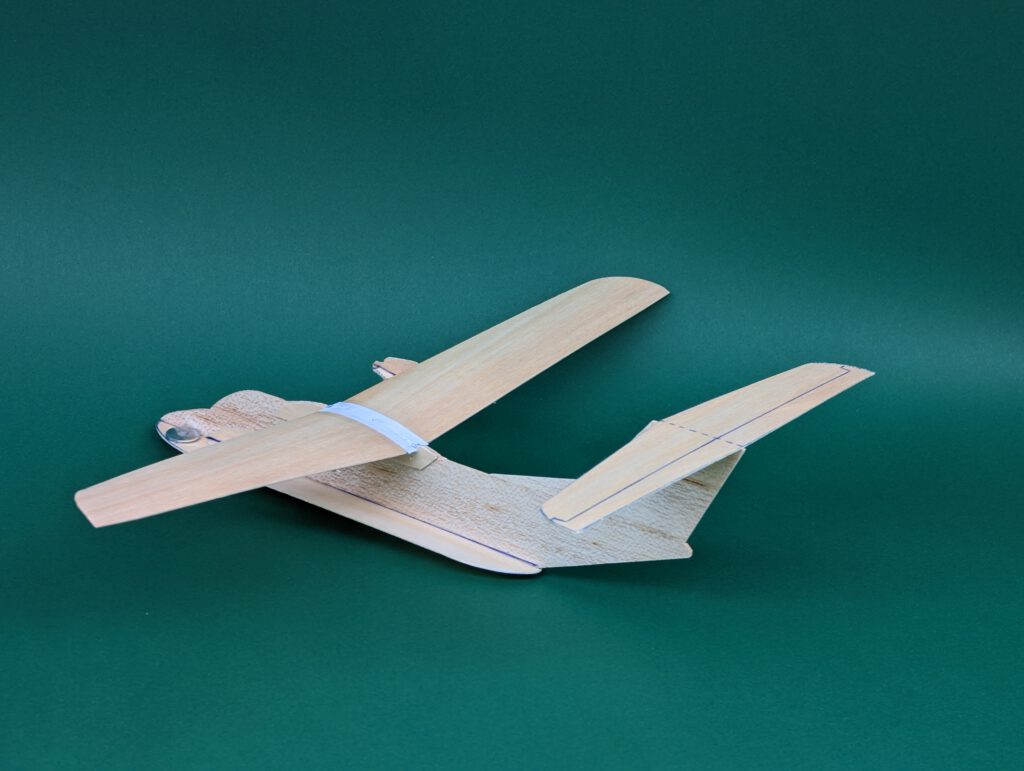

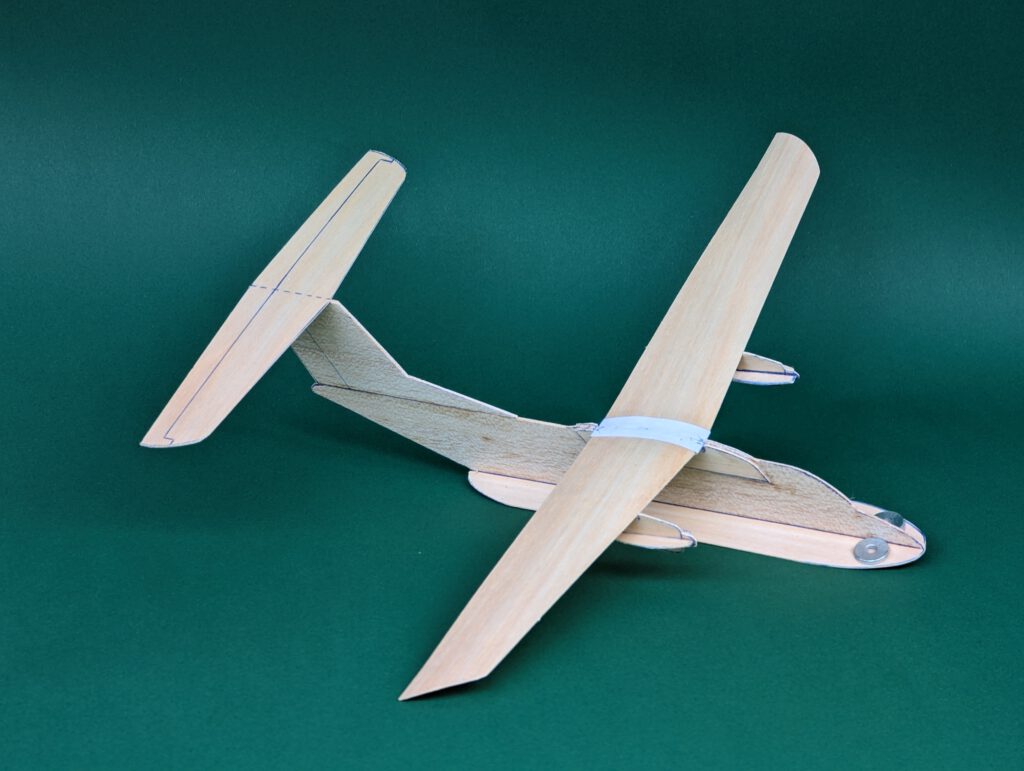

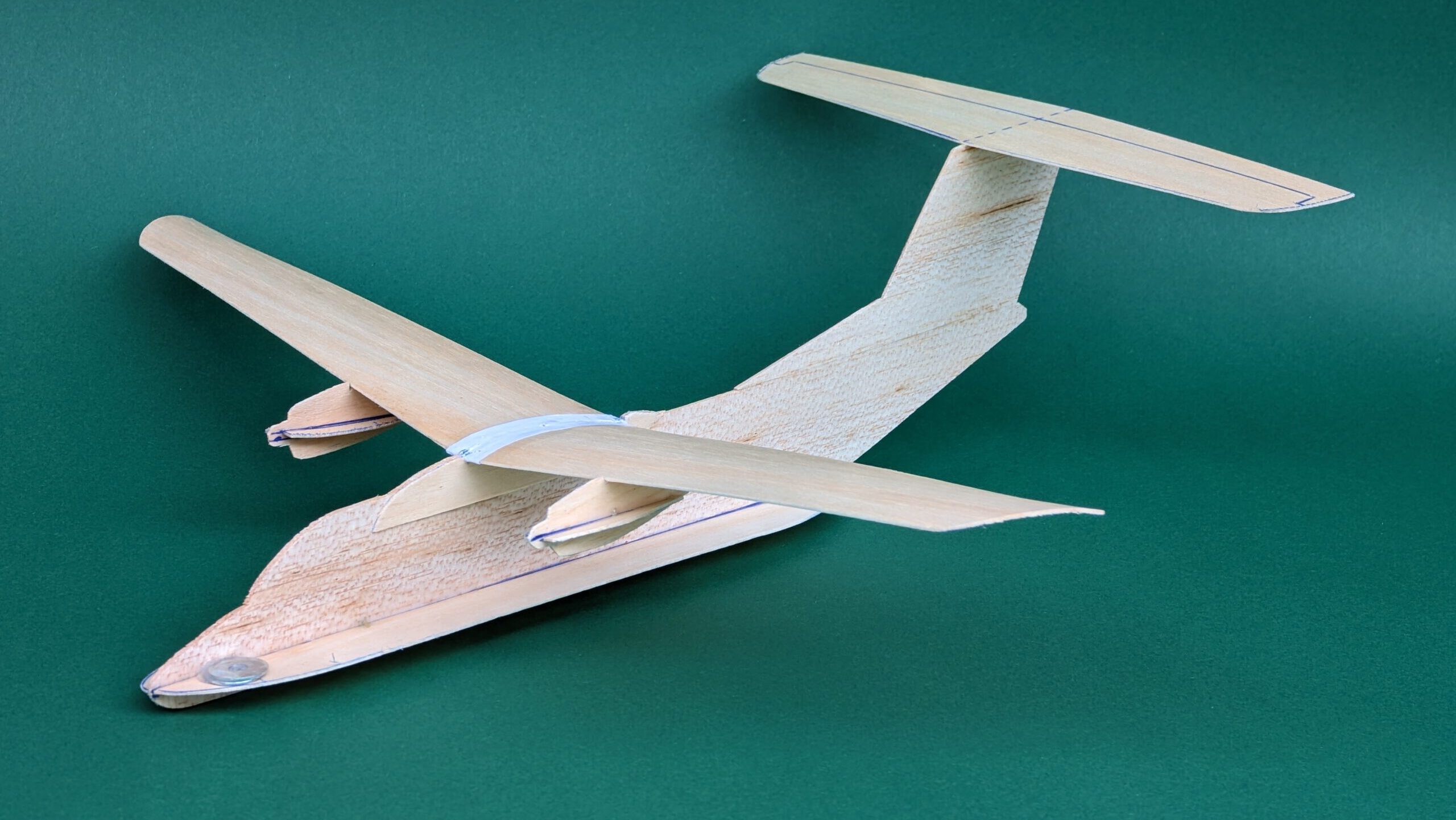

Span 42 cm / 16.5 in

Weight 18 g / 0.6 oz

The originally projected Desaer ATL-100 should have become a commuter aircraft for 19 passengers being developed as a joint venture by Brazil and Portugal. It was planned to introduce it in 2023 but it seems no maiden flight ever took place until today (summer 2024) as there is not one photo available on the internet. According to specifications published some years ago the ATL-100 has a span of 20 m / 66 ft, a length of 16 m / 52 ft 6 in and a max take off weight of 8,618 kg / 19,000 lb. Powerplants were to be two turboprop engines rated at 1,000 hp each. Following newest information there is a Desaer ATL-100H hybrid aircraft under development that combines electric and turboprop powerplants. Obviously so the older ATL-100 will remain a project only.

Building the balsa sheet chuck glider ATL-100.

Materials:

Fuselage: hard B 1.5 ; Fuselage side stiffener: B 0.8; fin: hard B 1.5; wing supports: B 1; wings: B 1; motorgondola – vertical and horizontal parts: B 1; horizontal stabilizer: 1 B; linen or cotton band width ½ in; Ballast: small piece of lead or scrap metal.

Assembly: (sorry, no photos available)

Cut out all balsa parts. Make slots for stiffeners into fuselage. Make slots into vertical motorgondola parts. Sand well. Transfer outlines of cockpit and side windows, rudders, elevators, flaps ec from paper to wood with pen.

Fuselage:

Fix fuselage on your building board with needles. Cement fin on fuselage and let dry. Cement side stiffener at 90 ° angle on right side of fuselage. Let dry. Repeat procedure on left side. Let dry. Cement wing support parts into their place on both sides of fuselage using clamps or clothespins.

Wings:

Fix one wing half on building board with needles. Underlay second half according to given dihedral and cement. Linen band should be used to strengthen wing center section. Put fuselage on so called “third hand” or fix fuselage on top of two equal books. Cement wing on curved (profiled) center fuselage section. Use needles to hold in place. Check symmetry at this stage. Mark position of motorgondolas.

Empennage:

Set and cement horizontal stab on fin using needles to hold in place. Check symmetry.

Final Assembly:

Cement curved (profiled) section of left vertical motorgondola part on wing using needles to hold in place. Remember to visual check to obtain symmetry. Let dry. Repeat this procedure on right side. Use „third hand“ for this procedure. Let dry. Add horizontal parts to motorgondolas.

Balance model in accordance to given CG on plan.

The profiled wing makes this model despite high wing loading a superb chuck glider.

Have a pleasant flight! (гарного польоту!)

Leave a Reply